Itse huomannut lähes kaikessa koodaamisessa että kun tavallaan valmis koodi on niin kannattaa aloittaa alusta kun tiedetään tarkasti miten koodi on ajateltu toimivaksi itsellä ainakin tällä kerralla välistä jää paljon turhaa koodia pois enkä ole kertaakaan saanut koodia toimimaan laakista.

-

PikanavigaatioAjankohtaista io-tech.fi uutiset Uutisia lyhyesti Muu uutiskeskustelu io-tech.fi artikkelit io-techin Youtube-videot Palaute, tiedotukset ja arvonnat

Tietotekniikka Prosessorit, ylikellotus, emolevyt ja muistit Näytönohjaimet Tallennus Kotelot ja virtalähteet Jäähdytys Konepaketit Kannettavat tietokoneet Buildit, setupit, kotelomodifikaatiot & DIY Oheislaitteet ja muut PC-komponentit

Tekniikkakeskustelut Ongelmat Yleinen rautakeskustelu Älypuhelimet, tabletit, älykellot ja muu mobiili Viihde-elektroniikka, audio ja kamerat Elektroniikka, rakentelu ja muut DIY-projektit Internet, tietoliikenne ja tietoturva Käyttäjien omat tuotetestit

Softakeskustelut Pelit, PC-pelaaminen ja pelikonsolit Ohjelmointi, pelikehitys ja muu sovelluskehitys Yleinen ohjelmistokeskustelu Testiohjelmat ja -tulokset

Muut keskustelut Autot ja liikenne Urheilu TV- & nettisarjat, elokuvat ja musiikki Ruoka & juoma Koti ja asuminen Yleistä keskustelua Politiikka ja yhteiskunta Hyvät tarjoukset Tekniikkatarjoukset Pelitarjoukset Ruoka- ja taloustarviketarjoukset Muut tarjoukset Black Friday 2025 -tarjoukset

Kauppa-alue

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Huomio: This feature may not be available in some browsers.

Lisää vaihtoehtoja

Tyylin valinta

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Autolaturi mökille varavoimaksi Arduinon avulla

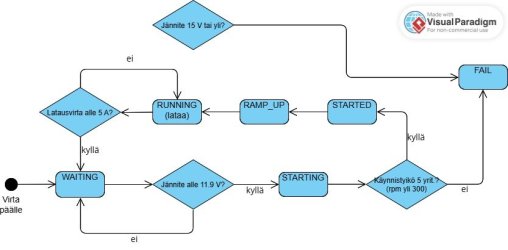

Tuossa mietin ainakin että kun startti ajaa konetta pyörittääkö se yli 300rpm eikö tuo raja kannattas nostaa jonnekin 1000rpm paikkeille vai paljonko tuollainen kone kiertää tyhjäkäynnillä.

Itse tekisin ehkä suoraan looppiin tuon yli15v jännitteen tutkimisen joka palauttaa heti tilan fail

Itse tekisin ehkä suoraan looppiin tuon yli15v jännitteen tutkimisen joka palauttaa heti tilan fail

- Liittynyt

- 10.07.2017

- Viestejä

- 958

@Nasty76 , kaikki kierroslukuarvot ja todennäköisesti myös alarajajännite ovat tässä vaiheessa vielä valistuneita arvauksia ja niitä ehtii sitten hienosäätää, kun koko systeemi on toimivana. Esim. tuo 300 kierrosta minuutissa lienee sitä luokkaa, että siinä voidaan ajatella, että moottori on käynnistynyt. Tuskin starttimoottori noin lujaa pyörittää moottoria ja helppohan sitä on tarpeen mukaan muuttaa ylemmäs.

Moottorin ilmoitettu tyhjäkäynti on 1 400 kierrosta minuutissa, starttimoottori kuitenkin tulisi irroittaa jo paljon ennen tätä, eli kun moottori alkaa niin sanotusti putputtamaan. Tyhjäkäyntiähän ei käytännössä tulla käyttämään koskaan, sillä moottori käynnistyy suoraan siihen kierrosnopeuteen, mihin se on asetettu. Veikkaanpa jotain puolikaasua, ehkä luokkaa 2 000 - 3 000 kierrosta minuutissa. Sitä suuremmalla syyllä startin olisi hyvä irrota moottorista jo ajoissa.

Moottorin ilmoitettu tyhjäkäynti on 1 400 kierrosta minuutissa, starttimoottori kuitenkin tulisi irroittaa jo paljon ennen tätä, eli kun moottori alkaa niin sanotusti putputtamaan. Tyhjäkäyntiähän ei käytännössä tulla käyttämään koskaan, sillä moottori käynnistyy suoraan siihen kierrosnopeuteen, mihin se on asetettu. Veikkaanpa jotain puolikaasua, ehkä luokkaa 2 000 - 3 000 kierrosta minuutissa. Sitä suuremmalla syyllä startin olisi hyvä irrota moottorista jo ajoissa.

Stopping- tila ei ole välttämätön mutta arduinon kannalta moottorin sammuminen on kuitenkin hidas tapahtuma, loop() ajaa monta kertaa sen aikana kun kone sammuu (sekunteja kuitenkin koko tapahtuma).

Ja waiting- tilassa ei tietenkään saa olla koodia joka hämääntyy siitä että moottorilla on vielä kierroksia enemmän kuin 0.

Riippuu myös miten sammutus ja käynnistys tapahtuu, oikeastaanhan pitäisi ensin hallitusti lopettaa lataus (= pwm pienelle), kääntää sammutuslähtö ja sitten odottaa että kierrokset/tärinä ilmaisee että on seis.

2 ensimmäistä menee tilanvaihdossa running -> waiting mutta missä odotetaan että on oikeasti sammunut ?

Yksi tapa olla lisätä stopping- tila odotusta varten ja vasta kun todetaan että on oikeasti sammunut niin sammutuslähdön nollaus ja tilanvaihto -> waiting.

Toinen vaihtoehto on tietysti sammutuslähdön palautus ajo-asentoon vasta silloin kun käynnistetään. Tyyliin sammutuslähdön nollaus, odotetaan esim 200ms koska rele on hidas ja sitten starttilähtö päälle jne. Ja tässä välissä delay(200) on ihan ok eikä kannata tehdä ajastimella.

Ja waiting- tilassa ei tietenkään saa olla koodia joka hämääntyy siitä että moottorilla on vielä kierroksia enemmän kuin 0.

Riippuu myös miten sammutus ja käynnistys tapahtuu, oikeastaanhan pitäisi ensin hallitusti lopettaa lataus (= pwm pienelle), kääntää sammutuslähtö ja sitten odottaa että kierrokset/tärinä ilmaisee että on seis.

2 ensimmäistä menee tilanvaihdossa running -> waiting mutta missä odotetaan että on oikeasti sammunut ?

Yksi tapa olla lisätä stopping- tila odotusta varten ja vasta kun todetaan että on oikeasti sammunut niin sammutuslähdön nollaus ja tilanvaihto -> waiting.

Toinen vaihtoehto on tietysti sammutuslähdön palautus ajo-asentoon vasta silloin kun käynnistetään. Tyyliin sammutuslähdön nollaus, odotetaan esim 200ms koska rele on hidas ja sitten starttilähtö päälle jne. Ja tässä välissä delay(200) on ihan ok eikä kannata tehdä ajastimella.

- Liittynyt

- 10.07.2017

- Viestejä

- 958

No niin, jotain edistystä. Nyt sentään startti toimii, muttei ihan oikein, viiveet ovat ainakin simulla pidemmät mitä pitäisi olla. Nyt tila ei kuitenkaan vaihtele hallitsemattomasti. Loop-funktiossa on case-break juttu käytössä, en tiedä onko tuo ihan oikein laitettu.

Lisäksi jännä juttu kun lisäsin tuon STOPPING-tilan, mutta sille ei sitten löytynytkään käyttöä, niin halusin sen poistaa. Sitten kävi niin, että ei mene kääntäjästä läpi, jos tuone #define STOPPING 6 -rivin poistaa. Herja tulee liquid crystal-kirjastosta, joka kyllä on oikein asennettu. Lisäksi tuota STOPPING-tilaa ei esiinny missään koodissa.

Ajastimien osalta häikkää oli, eli tuossa koodissa pitää olla ainakin tuo .started komento käytössä, muuten ajastin ei lähde päälle. Saattaa toisaalta johtua myös, jos on loopissa, niin se pitäisi osata laittaa sinne koodin sisään.

Tässä ajastinkirjaston testikoodi:

Varsinainen koodi:

Lisäksi jännä juttu kun lisäsin tuon STOPPING-tilan, mutta sille ei sitten löytynytkään käyttöä, niin halusin sen poistaa. Sitten kävi niin, että ei mene kääntäjästä läpi, jos tuone #define STOPPING 6 -rivin poistaa. Herja tulee liquid crystal-kirjastosta, joka kyllä on oikein asennettu. Lisäksi tuota STOPPING-tilaa ei esiinny missään koodissa.

Ajastimien osalta häikkää oli, eli tuossa koodissa pitää olla ainakin tuo .started komento käytössä, muuten ajastin ei lähde päälle. Saattaa toisaalta johtua myös, jos on loopissa, niin se pitäisi osata laittaa sinne koodin sisään.

Tässä ajastinkirjaston testikoodi:

C++:

#include <neotimer.h>

Neotimer testTime = Neotimer(2000); //2 second

void setup() {

Serial.begin(250000);

}

void loop() {

if (!testTime.started()) {

testTime.start();

}

if (testTime.done()) {

Serial.println("Tulosta 2 sek valein.");

testTime.reset();

}

}Varsinainen koodi:

C++:

// Generator control system for car alternator (Ford with PWM controlled charging voltage) and small engine

#define DEBUG_STATUS // Serial debug, comment to disable, downmost values

//#define DEBUG_MAIN //Serial debug, comment to disable, uppermost main function values

// System status variables (motorStatus)

#define WAITING 0

#define STARTING 1

#define STARTED 2

#define RAMP_UP 3

#define RUNNING 4

#define FAIL 5

#define STOPPING 6

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

#include <neotimer.h> // Non-blocking timer from Neotimer library

Neotimer motorTime = Neotimer(10000); // 10 second timer for startup detection

Neotimer stepTime = Neotimer(1000); // 1 second timer for PWM step interval

Neotimer shutTime = Neotimer(15000); // 15 second timer for engine shutdown (wait before switching PWM back to 100 %, electromagnet off)

Neotimer crankTime = Neotimer(4000); // 4 second timer, if problems to start, try at most 4 seconds continuous cranking

Neotimer crankWait = Neotimer(5000); // 5 second timer, if crank failed, wait 5 seconds before a new try

Neotimer voltageWait = Neotimer(2000); // 60 seconds timer, how long to wait with undervoltage & other assigned conditions, before the starting function executes

Neotimer serDelay = Neotimer(1000); // For serial print interval

LiquidCrystal_I2C lcd(0x27, 16, 2); // Create a new LiquidCrystal_I2C display object with the correct I2C address and display size

// Define the pins

const int currentPin = A0; // Information about current

const int voltagePin = A2; // Information about voltage

const int motorPin = 2; // Motor running pin (vibration sensor), HIGH = motor running, TEST purpose LOW

const int pwmPin = 9; // PWM output pin

const int relayPin = 4; // Shutdown relay control pin

const int rpmPin = 11; // RPM Hall Sensor input pin, sensor type: 3144

const int starterPin = 3; // Starter relay control pinn

// Current and voltage calculation

float voltageFactor = 5.00 / 1023.00; // Factor to convert ADC reading to voltage

// Define the points for current calculation / the line equation

float x1 = 0.500; // volts

float y1 = 0; // amps

float x2 = 4.005; // volts

float y2 = 150; // amps

// Calculate the slope and intercept

float m = (y2 - y1) / (x2 - x1);

float b = y1 - m * x1;

float currentCal = 1; // Variable to shift the whole current level

float sensVfactor = 20.00 / 4.9248; // 4.9248 volts = 20 volts, factor to convert high voltage to 0-5 V

//float current; // Store current value, actual value

int current; // For current testing, serial input

//float sensVoltage; // Store sensed voltage, actual value

int sensVoltage = 13; // For voltage testing, serial input

const int N = 25; // Number of current readings to average

const int Y = 25; // Number of sensed voltage readings to average

int readings[N]; // Array to store the current readings

int readingsV[Y]; // Array to store the sensed voltage readings

// PWM

int pwmValues[] = { 24, 41, 58, 77 }; // PWM duty cycle steps (ramp up), 77 = ~30 %, you can add steps, if needed

int currentPwmStep = 0;

// Motor state, starting and shutting down

int motorStatus; // 0=waiting, for low voltage 1=starting, 2=started, 3=ramping up pwm, 4=running, 5=stopping, 6=system or engine malfuntion, stopped

int startTry; // 0=not tried to start yet, 1=first try done, 2=second, 3=third, 4=fourth, 5=fifth

int startInterval; // 0=not waiting after start attempt, 1=waiting after start attempt

float startVoltage = 11.9; // Volts, under what voltage the starting function will execute

float shutCurrent = 5; // Amperes, below what charging current to execute the shutdown function

float upVoltage = 15; // Volts, max allowed voltage

float rpmTH = 300; // Revolutions per minute, rpm threshold greater than this to stop cranking (assume motor is started rpms over the threshold)

float rpmRun = 1800; // Revolutions per minute, the rpm greater than this is accounted as motor normal running

//RPM Calculation

int rpm = 0; //unsigned long rpm = 0; // Variable to store rpm value

unsigned long duration; // Sensor pulse in duration

// int lcdStep; //0=current display, 1=voltage display, not used at the time

void setup() {

Serial.begin(250000); // Start the serial communication

#ifdef DEBUG_MAIN

Serial.println("Setup...");

#endif

Wire.begin();

// Check if the LCD is connected

Wire.beginTransmission(0x27);

if (Wire.endTransmission() == 0) {

// LCD is connected, proceed with initialization

delay(50);

lcd.begin(16, 2);

lcd.backlight();

lcd.clear();

} else {

// LCD is not connected, continue without initializing the LCD

#ifdef DEBUG_MAIN

Serial.println("Ei LCD:ta. Ohitus.");

#endif

}

// Change timers on pins to change PWM freq to 122 Hz

// Pins D9 and D10 - 122 Hz

TCCR1A = 0b00000001; // 8bit

TCCR1B = 0b00000100; // x256 phase correct

// Make pins output/input

pinMode(currentPin, INPUT); // Information on charging current

pinMode(voltagePin, INPUT); // Information on voltage, for real use, delete _PULLUP

pinMode(motorPin, INPUT_PULLUP); // Vibration sensor in, for motor running detect, for real use, delete _PULLUP (it is for test purpose, pullup resistor)

pinMode(pwmPin, OUTPUT); // Alternator PWM output

pinMode(relayPin, OUTPUT); // Ignition relay pin

pinMode(rpmPin, INPUT_PULLUP); // RPM sensing pin

pinMode(starterPin, OUTPUT); // Engine starter relay pin

// Start Duty Cycle at 100 %, alternator electromagnet off, for starting the engine

analogWrite(pwmPin, 255);

#ifdef DEBUG_MAIN

Serial.println("Setup ok.");

#endif

}

void motorCrankState() { // Detection of undervoltage to trigger motor cranking function

if (sensVoltage < startVoltage) { // If motorStatus is WAITING and sensed voltage is less than start voltage, trigger cranking function

#ifdef DEBUG_MAIN

Serial.println("Jannitekynnys kaynnistykseen!");

#endif

if (!voltageWait.started()) { // Start the voltageWait timer only, if it has not been started yet

voltageWait.start(); // Start the voltageWait timer if it hasn't started yet

}

if (voltageWait.done()) { // Wait for voltageWait to be done before moving to the cranking of the engine

motorStatus = STARTING;

digitalWrite(relayPin, HIGH); // Switch ignition relay on

voltageWait.stop();

voltageWait.reset(); // Reset timer

}

}

}

void crank() { // Engine starting function

if (((startTry >= 0) && (startTry <= 4)) && (startInterval == 0)) { // If conditions are met, start executing

if (rpm <= rpmTH) { // If motor runs slower than the threshold, switch starter relay on

digitalWrite(starterPin, HIGH);

if (!crankTime.started()) {

crankTime.start(); // Start the crankTime timer if it hasn't started yet

}

if (crankTime.done()) { // If motor did not start during the crankTime, stop starting

digitalWrite(starterPin, LOW); // Switch starter relay off

crankTime.stop();

crankTime.reset(); // Reset timer

startTry += 1; // Add one attempt

startInterval = 1; // Start waiting time function after starting attempt

}

}

} else if (rpm > rpmTH) { // If motor runs faster than the threshold, switch starter relay off

digitalWrite(starterPin, LOW); // Switch starter pin off

startTry = 0;

motorStatus = STARTED;

crankTime.stop();

crankTime.reset(); // Reset timer

}

}

void Waiter() { // Wait after starting attempt

if (((startTry >= 0) && (startTry <= 4)) && (startInterval == 1)) { // If conditions are met, start executing

if (!crankWait.started()) {

crankWait.start(); // Start the crankWait timer if it hasn't started yet

}

if (crankWait.done()) { // If timer is done

startInterval = 0; // revert to state 0 (waiting time after start attempt ready)

crankWait.stop();

crankWait.reset(); // reset timer

}

}

}

void startFail() { // If engine did not start put system status to state 5 (malfunction)

if (startTry == 5) {

motorStatus = FAIL;

digitalWrite(starterPin, LOW); // Starter relay off

digitalWrite(relayPin, LOW); // Ignition switch relay off

#ifdef DEBUG_MAIN

Serial.println("Kaynnistysvirhe!");

#endif

lcd.setCursor(0, 0); // On lcd print "Engine start failed"

lcd.print("K");

lcd.print((char)0xe1);

lcd.print("ynnistys ");

lcd.setCursor(0, 1);

lcd.print("ep");

lcd.print((char)0xe1);

lcd.print("onnistui ");

}

}

void overvoltage() { // If voltage is over max voltage put motor status to FAIL (malfuntion) and shut down the ignition relay

if (sensVoltage >= upVoltage) {

motorStatus = FAIL;

digitalWrite(relayPin, LOW);

#ifdef DEBUG_MAIN

Serial.println("Ylijannite!");

#endif

lcd.setCursor(0, 0); // On lcd print "Overvoltage"

lcd.print("Ylij");

lcd.print((char)0xe1);

lcd.print("nnite ");

lcd.setCursor(0, 1);

lcd.print(" ");

}

}

void motorRunning() { // Engine running detection

if ((rpm > rpmRun) || (digitalRead(motorPin == HIGH))) { // If engine runs faster than rpmRun value (revolution per minute) assume motor is running normally

#ifdef DEBUG_MAIN

Serial.println("Kayntitieto!");

#endif

if (!motorTime.started()) {

motorTime.start(); // Start the motorTime timer if it hasn't started yet

}

if (motorTime.done()) { // Wait for motorTime to be done before moving to ramping up PWM

motorStatus = RAMP_UP;

motorTime.stop(); // Stop the timer

motorTime.reset(); // Reset the timer

#ifdef DEBUG_MAIN

Serial.println("Kay.");

#endif

}

}

}

void rampUp() { // Ramping up PWM

//Ramp pwm up

if (stepTime.repeat()) {

analogWrite(pwmPin, pwmValues[currentPwmStep]);

currentPwmStep++;

#ifdef DEBUG_MAIN

Serial.println("Ramp up...");

#endif

if (currentPwmStep >= sizeof(pwmValues) / sizeof(pwmValues[0])) { //Checking the pwm step count

motorStatus = RUNNING; // Motor running on normal charging state

stepTime.stop();

stepTime.reset(); // Reset the timer

}

}

}

void shutDown() { // Engine shutdown, execute relay

// If the charging current drops to 0 to shutCurrent and charging voltage is under upVoltage and motor is running

// start the shutdown function and turn off the relay

if ((current >= 0) && (current < shutCurrent) && (sensVoltage < upVoltage)) {

// if (digitalRead(motorPin) == HIGH) { // Vibration sensor

digitalWrite(relayPin, LOW); // Switch relay off

analogWrite(pwmPin, 15); // Duty Cycle to 5 % before running down engine

if (!shutTime.started()) {

shutTime.start();

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Stopped Duty Cycle at 100 %, alternator electromagnet off

lcd.setCursor(0, 0);

lcd.print("Sammutus "); // Print on lcd "Shutdown"

lcd.setCursor(0, 1);

lcd.print(" ");

motorStatus = WAITING; // Motor has run, battery is full, go back to waiting voltage

shutTime.stop(); // Reset the timer

shutTime.reset(); // Reset the timer

#ifdef DEBUG_MAIN

Serial.println("Sammutettu.");

#endif

}

}

}

//}

void lcdDisplay() { // Show values on lcd only when

if (motorStatus == RUNNING) {

lcd.setCursor(0, 0);

lcd.print("Virta: ");

lcd.setCursor(0, 1);

lcd.print((float)current);

lcd.print(" ");

lcd.setCursor(5, 1);

lcd.print(" A ");

lcd.setCursor(8, 0);

lcd.print("J");

lcd.print((char)0xe1);

lcd.print("nnite:");

lcd.setCursor(8, 1);

lcd.print((float)sensVoltage);

lcd.print(" ");

lcd.setCursor(13, 1);

lcd.print(" V ");

#ifdef DEBUG_MAIN

Serial.println("Virta LCD.");

#endif

}

if (motorStatus == WAITING || motorStatus == STARTING) {

lcd.setCursor(0, 0); // On lcd print "Waiting"

lcd.print("Odotetaan... ");

lcd.setCursor(0, 1);

lcd.print("J");

lcd.print((char)0xe1);

lcd.print("nnite: ");

lcd.print((float)sensVoltage);

lcd.print(" V");

}

}

void loop() {

// Calculate current from sensor reading

// Calculate the charging current from the average and display it on the LCD screen.

// Take N readings and store them in the array

// for (int i = 0; i < N; i++) {

// readings[i] = analogRead(currentPin);

// delay(1); //Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sum = 0;

// for (int i = 0; i < N; i++) {

// sum += readings[i];

// }

// float average = sum / N;

// float voltage = average * voltageFactor; // Convert ADC reading to voltage

// current = (m * voltage + b) * currentCal; // Convert voltage to current using the linear equation, correct with current calibration value if needed

// Calculate high voltage from voltage divider input

// Calculate the charging voltage from the average and display it on the LCD screen.

// Take Y readings and store them in the array

// for (int j = 0; j < Y; j++) {

// readingsV[j] = analogRead(voltagePin);

// delay(1); // Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sumV = 0;

// for (int j = 0; j < Y; j++) {

// sumV += readingsV[j];

// }

// float averageV = sumV / Y;

// float voltageV = averageV * voltageFactor; // Convert ADC reading to voltage

// sensVoltage = voltageV * sensVfactor; // Convert voltage to real voltage

// RPM Calculation from Hall Sensor input

// {

// duration = pulseIn(rpmPin, FALLING, 500000); // Times the amount of microseconds the motor is not timing IR, Times out after 100000 uS. Raise the timeout for slower RPM readings. .5 second

// rpm = 60000.0 / duration * 1000; // See above

// }

// Handling the motor status

switch (motorStatus) {

case WAITING:

motorCrankState();

lcdDisplay();

startFail();

overvoltage();

break;

case STARTING:

crank();

Waiter();

lcdDisplay();

startFail();

overvoltage();

break;

case STARTED:

motorRunning();

startFail();

overvoltage();

break;

case RAMP_UP:

rampUp();

lcdDisplay();

startFail();

overvoltage();

break;

case RUNNING:

startFail();

overvoltage();

break;

}

//Serial key input test code, write to various variables

#ifdef DEBUG_STATUS

if (Serial.available() > 0) {

char input = Serial.read();

switch (input) {

case '1':

rpm = 0;

break;

case '2':

rpm = 500;

break;

case '3':

rpm = 2000;

break;

case 'a':

current = 2;

break;

case 'b':

current = 20;

break;

case 'c':

current = 80;

break;

case 'z':

sensVoltage = 11;

break;

case 'x':

sensVoltage = 14;

break;

case 'y':

sensVoltage = 16;

break;

default:

Serial.println("Invalid input.");

return;

}

}

#endif

//Debug

#ifdef DEBUG_STATUS

Serial.print("Jannite: ");

Serial.print((float)sensVoltage);

Serial.println();

Serial.print("Virta: ");

Serial.print((float)current);

Serial.println();

Serial.print("Tila: ");

Serial.print(motorStatus);

Serial.println();

Serial.print("Start tila: ");

Serial.print(startTry);

Serial.println();

Serial.print("Odotus: ");

Serial.print(startInterval);

Serial.println();

Serial.print("RPM: ");

Serial.print(rpm);

Serial.println();

#endif

}- Liittynyt

- 10.07.2017

- Viestejä

- 958

Kiinanpojan tekoälyyn pyöräytin koodin ja käskin kirjoitella uusiksi nuo funktiot, ja nyt simulaation mukaan on ainakin toiminnallisesti jokseenkin toimiva koodi. Onkohan tilojen hallinta nyt niin, ettei esim. starttaus ala heti, kun moottorin nopeus laskee? Ainakin se teki tuon switch-case jutu erillä tavalla, huomasin omasta sähhellyksestäni, että logiikkani petti ainakin siinä, että funktiot olivat ehkä väärissä paikoissa. Uuteen tekoälykoodiin täytyy lisätä vielä vikatilat.

C++:

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

#include <neotimer.h>

// System status variables

#define WAITING 0

#define STARTING 1

#define STARTED 2

#define RAMP_UP 3

#define RUNNING 4

#define FAIL 5

#define STOPPING 6

// Pin definitions

const int currentPin = A0;

const int voltagePin = A2;

const int motorPin = 2;

const int pwmPin = 9;

const int relayPin = 4;

const int rpmPin = 11;

const int starterPin = 3;

// Timers

Neotimer motorTime = Neotimer(10000); // 10 seconds for startup detection

Neotimer stepTime = Neotimer(1000); // 1 second for PWM step interval

Neotimer shutTime = Neotimer(15000); // 15 seconds for engine shutdown

Neotimer crankTime = Neotimer(4000); // 4 seconds for cranking

Neotimer crankWait = Neotimer(5000); // 5 seconds wait after failed crank

Neotimer voltageWait = Neotimer(2000); // 2 seconds wait for undervoltage

// LCD

LiquidCrystal_I2C lcd(0x27, 16, 2);

// Variables

int motorStatus = WAITING;

int startTry = 0;

int startInterval = 0;

int currentPwmStep = 0;

int pwmValues[] = { 24, 41, 58, 77 }; // PWM steps

// Current and voltage calculation

float voltageFactor = 5.00 / 1023.00; // Factor to convert ADC reading to voltage

// Define the points for current calculation / the line equation

float x1 = 0.500; // volts

float y1 = 0; // amps

float x2 = 4.005; // volts

float y2 = 150; // amps

// Calculate the slope and intercept

float m = (y2 - y1) / (x2 - x1);

float b = y1 - m * x1;

float currentCal = 1; // Variable to shift the whole current level

float sensVfactor = 20.00 / 4.9248; // 4.9248 volts = 20 volts, factor to convert high voltage to 0-5 V

const int N = 25; // Number of current readings to average

const int Y = 25; // Number of sensed voltage readings to average

int readings[N]; // Array to store the current readings

int readingsV[Y]; // Array to store the sensed voltage readings

float sensVoltage = 12.0; // Example voltage

float current = 0.0; // Example current

//RPM Calculation

int rpm = 0; //unsigned long rpm = 0;

unsigned long duration; // Sensor pulse in duration

void setup() {

Serial.begin(250000);

// Change timers on pins to change PWM freq to 122 Hz

// Pins D9 and D10 - 122 Hz

TCCR1A = 0b00000001; // 8bit

TCCR1B = 0b00000100; // x256 phase correct

// Initialize I2C and check if LCD is connected

Wire.begin();

Wire.beginTransmission(0x27);

if (Wire.endTransmission() == 0) {

// LCD is connected, proceed with initialization

lcd.begin(16, 2);

lcd.backlight();

lcd.clear();

} else {

// LCD is not connected, continue without initializing the LCD

Serial.println("LCD not connected. Skipping.");

}

// Pin modes

pinMode(currentPin, INPUT);

pinMode(voltagePin, INPUT);

pinMode(motorPin, INPUT_PULLUP);

pinMode(pwmPin, OUTPUT);

pinMode(relayPin, OUTPUT);

pinMode(rpmPin, INPUT_PULLUP);

pinMode(starterPin, OUTPUT);

analogWrite(pwmPin, 255); // Start with PWM off

}

void motorCrankState() {

if (sensVoltage < 11.9 && motorStatus == WAITING) {

if (!voltageWait.started()) {

voltageWait.start();

}

if (voltageWait.done()) {

motorStatus = STARTING;

digitalWrite(relayPin, HIGH);

voltageWait.stop();

voltageWait.reset();

}

}

}

void crank() {

if (startTry < 5 && startInterval == 0) {

if (rpm <= 300) {

digitalWrite(starterPin, HIGH);

if (!crankTime.started()) {

crankTime.start();

}

if (crankTime.done()) {

digitalWrite(starterPin, LOW);

crankTime.stop();

crankTime.reset();

startTry++;

startInterval = 1;

}

} else if (rpm > 300) {

digitalWrite(starterPin, LOW);

startTry = 0;

motorStatus = STARTED;

crankTime.stop();

crankTime.reset();

}

}

}

void Waiter() {

if (startInterval == 1) {

if (!crankWait.started()) {

crankWait.start();

}

if (crankWait.done()) {

startInterval = 0;

crankWait.stop();

crankWait.reset();

}

}

}

void motorRunning() {

if ((rpm > 1800 || digitalRead(motorPin) == HIGH) && motorStatus == STARTED) {

if (!motorTime.started()) {

motorTime.start();

}

if (motorTime.done()) {

motorStatus = RAMP_UP;

motorTime.stop();

motorTime.reset();

}

}

}

void rampUp() {

if (stepTime.repeat()) {

analogWrite(pwmPin, pwmValues[currentPwmStep]);

currentPwmStep++;

if (currentPwmStep >= sizeof(pwmValues) / sizeof(pwmValues[0])) {

motorStatus = RUNNING;

stepTime.stop();

stepTime.reset();

}

}

}

void shutDown() {

if (current < 5 && sensVoltage < 15 && motorStatus == RUNNING) {

digitalWrite(relayPin, LOW); // Turn off the ignition relay

analogWrite(pwmPin, 15); // Set PWM to 5% (reduce alternator load)

if (!shutTime.started()) {

shutTime.start(); // Start the shutdown timer

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off)

motorStatus = WAITING; // Revert to WAITING state

shutTime.stop(); // Stop the timer

shutTime.reset(); // Reset the timer

// Clear LCD and display shutdown message

lcd.setCursor(0, 0);

lcd.print("Shutdown ");

lcd.setCursor(0, 1);

lcd.print(" ");

}

}

}

void lcdDisplay() {

if (motorStatus == RUNNING) {

lcd.setCursor(0, 0);

lcd.print("Current: ");

lcd.print(current);

lcd.print(" A");

lcd.setCursor(0, 1);

lcd.print("Voltage: ");

lcd.print(sensVoltage);

lcd.print(" V");

} else if (motorStatus == WAITING || motorStatus == STARTING) {

lcd.setCursor(0, 0);

lcd.print("Waiting...");

lcd.setCursor(0, 1);

lcd.print("Voltage: ");

lcd.print(sensVoltage);

lcd.print(" V");

}

}

void loop() {

// Calculate current from sensor reading

// Calculate the charging current from the average and display it on the LCD screen.

// Take N readings and store them in the array

// for (int i = 0; i < N; i++) {

// readings[i] = analogRead(currentPin);

// delay(1); //Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sum = 0;

// for (int i = 0; i < N; i++) {

// sum += readings[i];

// }

// float average = sum / N;

// float voltage = average * voltageFactor; // Convert ADC reading to voltage

// current = (m * voltage + b) * currentCal; // Convert voltage to current using the linear equation, correct with current calibration value if needed

// Calculate high voltage from voltage divider input

// Calculate the charging voltage from the average and display it on the LCD screen.

// Take Y readings and store them in the array

// for (int j = 0; j < Y; j++) {

// readingsV[j] = analogRead(voltagePin);

// delay(1); // Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sumV = 0;

// for (int j = 0; j < Y; j++) {

// sumV += readingsV[j];

// }

// float averageV = sumV / Y;

// float voltageV = averageV * voltageFactor; // Convert ADC reading to voltage

// sensVoltage = voltageV * sensVfactor; // Convert voltage to real voltage

// RPM Calculation from Hall Sensor input

// {

// duration = pulseIn(rpmPin, FALLING, 500000); // Times the amount of microseconds the motor is not timing IR, Times out after 100000 uS. Raise the timeout for slower RPM readings. .5 second

// rpm = 60000.0 / duration * 1000; // See above

// }

// Simulate sensor readings via Serial input

if (Serial.available() > 0) {

char input = Serial.read();

switch (input) {

case '1':

rpm = 0;

break;

case '2':

rpm = 500;

break;

case '3':

rpm = 2000;

break;

case 'a':

current = 2;

break;

case 'b':

current = 20;

break;

case 'c':

current = 80;

break;

case 'z':

sensVoltage = 11;

break;

case 'x':

sensVoltage = 14;

break;

case 'y':

sensVoltage = 16;

break;

default:

Serial.println("Invalid input.");

return;

}

}

// Handle motor status

switch (motorStatus) {

case WAITING:

motorCrankState();

lcdDisplay();

break;

case STARTING:

crank();

Waiter();

lcdDisplay();

break;

case STARTED:

motorRunning();

break;

case RAMP_UP:

rampUp();

lcdDisplay();

break;

case RUNNING:

shutDown();

lcdDisplay();

break;

}

// Debug output

Serial.print("Voltage: ");

Serial.print(sensVoltage);

Serial.print(" V, Current: ");

Serial.print(current);

Serial.print(" A, RPM: ");

Serial.print(rpm);

Serial.print(", Status: ");

Serial.println(motorStatus);

}Lisäksi jännä juttu kun lisäsin tuon STOPPING-tilan, mutta sille ei sitten löytynytkään käyttöä, niin halusin sen poistaa. Sitten kävi niin, että ei mene kääntäjästä läpi, jos tuone #define STOPPING 6 -rivin poistaa. Herja tulee liquid crystal-kirjastosta, joka kyllä on oikein asennettu. Lisäksi tuota STOPPING-tilaa ei esiinny missään koodissa.

Tähän ei voi auttaa ellet laita sitä koko virheilmoitusta mukaan.

Yleisempi ongelma on se että yrittää itse määrittää jotain joka on jo olemassa.

Kiinanpojan tekoälyyn pyöräytin koodin ja käskin kirjoitella uusiksi nuo funktiot, ja nyt simulaation mukaan on ainakin toiminnallisesti jokseenkin toimiva koodi. Onkohan tilojen hallinta nyt niin, ettei esim. starttaus ala heti, kun moottorin nopeus laskee? Ainakin se teki tuon switch-case jutu erillä tavalla, huomasin omasta sähhellyksestäni, että logiikkani petti ainakin siinä, että funktiot olivat ehkä väärissä paikoissa. Uuteen tekoälykoodiin täytyy lisätä vielä vikatilat.

C++:#include <Wire.h> #include <LiquidCrystal_I2C.h> #include <neotimer.h> // System status variables #define WAITING 0 #define STARTING 1 #define STARTED 2 #define RAMP_UP 3 #define RUNNING 4 #define FAIL 5 #define STOPPING 6 // Pin definitions const int currentPin = A0; const int voltagePin = A2; const int motorPin = 2; const int pwmPin = 9; const int relayPin = 4; const int rpmPin = 11; const int starterPin = 3; // Timers Neotimer motorTime = Neotimer(10000); // 10 seconds for startup detection Neotimer stepTime = Neotimer(1000); // 1 second for PWM step interval Neotimer shutTime = Neotimer(15000); // 15 seconds for engine shutdown Neotimer crankTime = Neotimer(4000); // 4 seconds for cranking Neotimer crankWait = Neotimer(5000); // 5 seconds wait after failed crank Neotimer voltageWait = Neotimer(2000); // 2 seconds wait for undervoltage // LCD LiquidCrystal_I2C lcd(0x27, 16, 2); // Variables int motorStatus = WAITING; int startTry = 0; int startInterval = 0; int currentPwmStep = 0; int pwmValues[] = { 24, 41, 58, 77 }; // PWM steps // Current and voltage calculation float voltageFactor = 5.00 / 1023.00; // Factor to convert ADC reading to voltage // Define the points for current calculation / the line equation float x1 = 0.500; // volts float y1 = 0; // amps float x2 = 4.005; // volts float y2 = 150; // amps // Calculate the slope and intercept float m = (y2 - y1) / (x2 - x1); float b = y1 - m * x1; float currentCal = 1; // Variable to shift the whole current level float sensVfactor = 20.00 / 4.9248; // 4.9248 volts = 20 volts, factor to convert high voltage to 0-5 V const int N = 25; // Number of current readings to average const int Y = 25; // Number of sensed voltage readings to average int readings[N]; // Array to store the current readings int readingsV[Y]; // Array to store the sensed voltage readings float sensVoltage = 12.0; // Example voltage float current = 0.0; // Example current //RPM Calculation int rpm = 0; //unsigned long rpm = 0; unsigned long duration; // Sensor pulse in duration void setup() { Serial.begin(250000); // Change timers on pins to change PWM freq to 122 Hz // Pins D9 and D10 - 122 Hz TCCR1A = 0b00000001; // 8bit TCCR1B = 0b00000100; // x256 phase correct // Initialize I2C and check if LCD is connected Wire.begin(); Wire.beginTransmission(0x27); if (Wire.endTransmission() == 0) { // LCD is connected, proceed with initialization lcd.begin(16, 2); lcd.backlight(); lcd.clear(); } else { // LCD is not connected, continue without initializing the LCD Serial.println("LCD not connected. Skipping."); } // Pin modes pinMode(currentPin, INPUT); pinMode(voltagePin, INPUT); pinMode(motorPin, INPUT_PULLUP); pinMode(pwmPin, OUTPUT); pinMode(relayPin, OUTPUT); pinMode(rpmPin, INPUT_PULLUP); pinMode(starterPin, OUTPUT); analogWrite(pwmPin, 255); // Start with PWM off } void motorCrankState() { if (sensVoltage < 11.9 && motorStatus == WAITING) { if (!voltageWait.started()) { voltageWait.start(); } if (voltageWait.done()) { motorStatus = STARTING; digitalWrite(relayPin, HIGH); voltageWait.stop(); voltageWait.reset(); } } } void crank() { if (startTry < 5 && startInterval == 0) { if (rpm <= 300) { digitalWrite(starterPin, HIGH); if (!crankTime.started()) { crankTime.start(); } if (crankTime.done()) { digitalWrite(starterPin, LOW); crankTime.stop(); crankTime.reset(); startTry++; startInterval = 1; } } else if (rpm > 300) { digitalWrite(starterPin, LOW); startTry = 0; motorStatus = STARTED; crankTime.stop(); crankTime.reset(); } } } void Waiter() { if (startInterval == 1) { if (!crankWait.started()) { crankWait.start(); } if (crankWait.done()) { startInterval = 0; crankWait.stop(); crankWait.reset(); } } } void motorRunning() { if ((rpm > 1800 || digitalRead(motorPin) == HIGH) && motorStatus == STARTED) { if (!motorTime.started()) { motorTime.start(); } if (motorTime.done()) { motorStatus = RAMP_UP; motorTime.stop(); motorTime.reset(); } } } void rampUp() { if (stepTime.repeat()) { analogWrite(pwmPin, pwmValues[currentPwmStep]); currentPwmStep++; if (currentPwmStep >= sizeof(pwmValues) / sizeof(pwmValues[0])) { motorStatus = RUNNING; stepTime.stop(); stepTime.reset(); } } } void shutDown() { if (current < 5 && sensVoltage < 15 && motorStatus == RUNNING) { digitalWrite(relayPin, LOW); // Turn off the ignition relay analogWrite(pwmPin, 15); // Set PWM to 5% (reduce alternator load) if (!shutTime.started()) { shutTime.start(); // Start the shutdown timer } if (shutTime.done()) { analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off) motorStatus = WAITING; // Revert to WAITING state shutTime.stop(); // Stop the timer shutTime.reset(); // Reset the timer // Clear LCD and display shutdown message lcd.setCursor(0, 0); lcd.print("Shutdown "); lcd.setCursor(0, 1); lcd.print(" "); } } } void lcdDisplay() { if (motorStatus == RUNNING) { lcd.setCursor(0, 0); lcd.print("Current: "); lcd.print(current); lcd.print(" A"); lcd.setCursor(0, 1); lcd.print("Voltage: "); lcd.print(sensVoltage); lcd.print(" V"); } else if (motorStatus == WAITING || motorStatus == STARTING) { lcd.setCursor(0, 0); lcd.print("Waiting..."); lcd.setCursor(0, 1); lcd.print("Voltage: "); lcd.print(sensVoltage); lcd.print(" V"); } } void loop() { // Calculate current from sensor reading // Calculate the charging current from the average and display it on the LCD screen. // Take N readings and store them in the array // for (int i = 0; i < N; i++) { // readings[i] = analogRead(currentPin); // delay(1); //Wait for a millisecond between readings // } // Calculate the average of the N readings // float sum = 0; // for (int i = 0; i < N; i++) { // sum += readings[i]; // } // float average = sum / N; // float voltage = average * voltageFactor; // Convert ADC reading to voltage // current = (m * voltage + b) * currentCal; // Convert voltage to current using the linear equation, correct with current calibration value if needed // Calculate high voltage from voltage divider input // Calculate the charging voltage from the average and display it on the LCD screen. // Take Y readings and store them in the array // for (int j = 0; j < Y; j++) { // readingsV[j] = analogRead(voltagePin); // delay(1); // Wait for a millisecond between readings // } // Calculate the average of the N readings // float sumV = 0; // for (int j = 0; j < Y; j++) { // sumV += readingsV[j]; // } // float averageV = sumV / Y; // float voltageV = averageV * voltageFactor; // Convert ADC reading to voltage // sensVoltage = voltageV * sensVfactor; // Convert voltage to real voltage // RPM Calculation from Hall Sensor input // { // duration = pulseIn(rpmPin, FALLING, 500000); // Times the amount of microseconds the motor is not timing IR, Times out after 100000 uS. Raise the timeout for slower RPM readings. .5 second // rpm = 60000.0 / duration * 1000; // See above // } // Simulate sensor readings via Serial input if (Serial.available() > 0) { char input = Serial.read(); switch (input) { case '1': rpm = 0; break; case '2': rpm = 500; break; case '3': rpm = 2000; break; case 'a': current = 2; break; case 'b': current = 20; break; case 'c': current = 80; break; case 'z': sensVoltage = 11; break; case 'x': sensVoltage = 14; break; case 'y': sensVoltage = 16; break; default: Serial.println("Invalid input."); return; } } // Handle motor status switch (motorStatus) { case WAITING: motorCrankState(); lcdDisplay(); break; case STARTING: crank(); Waiter(); lcdDisplay(); break; case STARTED: motorRunning(); break; case RAMP_UP: rampUp(); lcdDisplay(); break; case RUNNING: shutDown(); lcdDisplay(); break; } // Debug output Serial.print("Voltage: "); Serial.print(sensVoltage); Serial.print(" V, Current: "); Serial.print(current); Serial.print(" A, RPM: "); Serial.print(rpm); Serial.print(", Status: "); Serial.println(motorStatus); }

No ainakin lcdDisplay() kuuluu oikeastaan tuon switch-case ulkopuolelle, siis tilasta riippumatta päivitetään näyttö. Ja siellä funktiossa onkin jo oma tarkastus mitä missäkin tilassa näytetään niin voi kutsua joka kierroksella.

Sanoisin että crank() ja waiter() kannattaa yhdistää.

shutdown() ei tee mitään jos jännite on > 15, se taitaa olla turha ehto tuolla jos jännite > 15 tulee johonkin virhetarkastukseen tilojen ulkopuolelle.

Parempi ehkä tehdä sellainen "sammuta moottori"- funktio jota voit kutsua tuolta shutdown()/ "ollaan ajossa, pitää sammuttaa koska akku täynnä" ja myös "traaginen virhe, sammuta moottori". Samat jutut pitää kuitenkin suurimmaksi osaksi tehdä molemmissa tapauksissa.

Tarkasta sitten myös kommentoidusta osasta jännitteen ja virran mittaukset, ne m, b, x1, x2, y1, y2 laskennat on ihan turhia... Tarvitset molemmille vain mittauksen ja arvon skaalauksen oikealle alueelle.

"Onkohan tilojen hallinta nyt niin, ettei esim. starttaus ala heti, kun moottorin nopeus laskee"

-> ainakaan pikakatsauksella ei vaikuta siltä koska crank() kutsutaan vain starting- tilassa. Tietysti jos startin aikana kierrokset laskevat niin sitten kyllä.

- Liittynyt

- 10.07.2017

- Viestejä

- 958

@ississ, jännite- ja virtamittauksiin ei ole ehty muutoksia. Tekoäly poisti ne kokonaan, mutta liitin takaisin ne. On kyllä tiedossa, kuten aiemminkin olet maininnut, ettei tuollainen virran ja jännitteen laskenta ole ihan optimaalisin ratkaisu.

Yritin kyllä saada toimimaan sen map() -funktiolla tms. vastaavalla ja se ei harmi kyllä onnistunut. Tämä hieman tosiaankin varmaan turhan järeä systeemi kuitenkin on toiminut. Esim. tuo Pololun anturihan on 0 A ~ 0,5 V ja 150 A ~ 4 V.

Yritin kyllä saada toimimaan sen map() -funktiolla tms. vastaavalla ja se ei harmi kyllä onnistunut. Tämä hieman tosiaankin varmaan turhan järeä systeemi kuitenkin on toiminut. Esim. tuo Pololun anturihan on 0 A ~ 0,5 V ja 150 A ~ 4 V.

- Liittynyt

- 10.07.2017

- Viestejä

- 958

Huhhuh, pakko laittaa koodi tänne, kun olen tehnyt siihen muutoksia. Pelkään, etten vain tee sille kohta "meisselihalvausta".

Muutoksia:

-FAIL tilalle käyttöä, esim. ylijännite ja epäonnistunut käynnistys, mutta myös nyt kierroluvun tarkastelu. Lisäsin myös samalla tyylillä värinäanturin tarkastelun, mutta voi olla, että koko anturi jätetään pois, koska kierroslukuanturi tulee olemaan keskeinen tätä systeemiä käynnistyksen vuoksi.

-lcd:tä päivitetty

-käynnistysfunktiossa (crank()) puuttui ajastimen sammutus ja nollaus, mikäli jännite heilahtelee ylös. Tämä on hyvin todennäköinen tilanne. Hyvin näytti pelevaan simulaattorissa, vaikka tuossa nyt tulee tuo else -ehto, mutta käsittääkseni tuo switch-case -kombinaatio ehkäisee tuon ajamista koko ajan.

Ja seuraavana, jos koodi vielä toimii, tulisi testata vielä fyysisesti skoopilla PWM sekä releet. Releet pitää käskyttää niin (HIGH/LOW), että sytytysvirtarele ei johda, kun sille ei anneta käskyä ja starttireleen ei myöskään johda, ku sitä ei käskytetä. Toki releestä voi vaihtaa nuo kummin päin vaan. Pitää vaan varmistua, ettei myöskään koodissa ole mitään ristiriitojen releiden ohjauksessa niin, että rele voisi jäädä väärään asentoon. Siltä se ei Arduino simulaattorin mukaan näytä, mikä on hyvä asia.

Muutoksia:

-FAIL tilalle käyttöä, esim. ylijännite ja epäonnistunut käynnistys, mutta myös nyt kierroluvun tarkastelu. Lisäsin myös samalla tyylillä värinäanturin tarkastelun, mutta voi olla, että koko anturi jätetään pois, koska kierroslukuanturi tulee olemaan keskeinen tätä systeemiä käynnistyksen vuoksi.

-lcd:tä päivitetty

-käynnistysfunktiossa (crank()) puuttui ajastimen sammutus ja nollaus, mikäli jännite heilahtelee ylös. Tämä on hyvin todennäköinen tilanne. Hyvin näytti pelevaan simulaattorissa, vaikka tuossa nyt tulee tuo else -ehto, mutta käsittääkseni tuo switch-case -kombinaatio ehkäisee tuon ajamista koko ajan.

Ja seuraavana, jos koodi vielä toimii, tulisi testata vielä fyysisesti skoopilla PWM sekä releet. Releet pitää käskyttää niin (HIGH/LOW), että sytytysvirtarele ei johda, kun sille ei anneta käskyä ja starttireleen ei myöskään johda, ku sitä ei käskytetä. Toki releestä voi vaihtaa nuo kummin päin vaan. Pitää vaan varmistua, ettei myöskään koodissa ole mitään ristiriitojen releiden ohjauksessa niin, että rele voisi jäädä väärään asentoon. Siltä se ei Arduino simulaattorin mukaan näytä, mikä on hyvä asia.

C++:

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

#include <neotimer.h>

// System status variables

#define WAITING 0

#define STARTING 1

#define STARTED 2

#define RAMP_UP 3

#define RUNNING 4

#define FAIL 5

#define STOPPING 6

// Pin definitions

const int currentPin = A0;

const int voltagePin = A2;

const int motorPin = 2;

const int pwmPin = 9;

const int relayPin = 4;

const int rpmPin = 11;

const int starterPin = 3;

// Timers

Neotimer motorTime = Neotimer(10000); // 10 seconds for startup detection

Neotimer stepTime = Neotimer(1000); // 1 second for PWM step interval

Neotimer shutTime = Neotimer(15000); // 15 seconds for engine shutdown

Neotimer crankTime = Neotimer(4000); // 4 seconds for cranking

Neotimer crankWait = Neotimer(5000); // 5 seconds wait after failed crank

Neotimer voltageWait = Neotimer(10000); // 10 seconds wait for undervoltage

Neotimer sensorTime = Neotimer(5000); // 5 seconds check time for vibration sensor condition on RUNNNING status

// LCD

LiquidCrystal_I2C lcd(0x27, 16, 2);

// Variables

int motorStatus = WAITING;

int startTry = 0;

int startInterval = 0; // Waiting time on after start attempt

int currentPwmStep = 0;

int pwmValues[] = { 32, 64, 96, 128 }; // PWM steps

// Current and voltage calculation

float voltageFactor = 5.00 / 1023.00; // Factor to convert ADC reading to voltage

// Define the points for current calculation / the line equation

float x1 = 0.500; // volts

float y1 = 0; // amps

float x2 = 4.005; // volts

float y2 = 150; // amps

// Calculate the slope and intercept

float m = (y2 - y1) / (x2 - x1);

float b = y1 - m * x1;

float currentCal = 1; // Variable to shift the whole current level

float sensVfactor = 20.00 / 4.9248; // 4.9248 volts = 20 volts, factor to convert high voltage to 0-5 V

const int N = 25; // Number of current readings to average

const int Y = 25; // Number of sensed voltage readings to average

int readings[N]; // Array to store the current readings

int readingsV[Y]; // Array to store the sensed voltage readings

float sensVoltage = 12.0; // Example voltage

float current = 0.0; // Example current

//RPM Calculation

int rpm = 0; //unsigned long rpm = 0;

unsigned long duration; // Sensor pulse in duration

void setup() {

Serial.begin(250000);

// Change timers on pins to change PWM freq to 122 Hz

// Pins D9 and D10 - 122 Hz

TCCR1A = 0b00000001; // 8bit

TCCR1B = 0b00000100; // x256 phase correct

// Initialize I2C and check if LCD is connected

Wire.begin();

Wire.beginTransmission(0x27);

if (Wire.endTransmission() == 0) {

// LCD is connected, proceed with initialization

lcd.begin(16, 2);

lcd.backlight();

lcd.clear();

} else {

// LCD is not connected, continue without initializing the LCD

Serial.println("LCD not connected. Skipping.");

}

// Pin modes

pinMode(currentPin, INPUT);

pinMode(voltagePin, INPUT);

pinMode(motorPin, INPUT_PULLUP);

pinMode(pwmPin, OUTPUT);

pinMode(relayPin, OUTPUT);

pinMode(rpmPin, INPUT_PULLUP);

pinMode(starterPin, OUTPUT);

analogWrite(pwmPin, 255); // Start with PWM off

}

void motorCrankState() {

if (sensVoltage < 11.9 && motorStatus == WAITING) {

if (!voltageWait.started()) {

voltageWait.start();

}

if (voltageWait.done()) {

motorStatus = STARTING;

digitalWrite(relayPin, HIGH);

voltageWait.stop();

voltageWait.reset();

}

} else {

voltageWait.stop();

voltageWait.reset();

}

}

void crank() {

if (startTry < 5 && startInterval == 0) {

if (rpm <= 300) {

digitalWrite(starterPin, HIGH);

if (!crankTime.started()) {

crankTime.start();

}

if (crankTime.done()) {

digitalWrite(starterPin, LOW);

crankTime.stop();

crankTime.reset();

startTry++;

startInterval = 1;

}

} else if (rpm > 300) {

digitalWrite(starterPin, LOW);

startTry = 0;

motorStatus = STARTED;

crankTime.stop();

crankTime.reset();

}

}

}

void Waiter() {

if (startInterval == 1) {

if (!crankWait.started()) {

crankWait.start();

}

if (crankWait.done()) {

startInterval = 0;

crankWait.stop();

crankWait.reset();

}

}

}

void motorRunning() {

if ((rpm > 1800 || digitalRead(motorPin) == HIGH) && motorStatus == STARTED) {

if (!motorTime.started()) {

motorTime.start();

}

if (motorTime.done()) {

motorStatus = RAMP_UP;

motorTime.stop();

motorTime.reset();

}

}

}

void rampUp() {

if (stepTime.repeat()) {

analogWrite(pwmPin, pwmValues[currentPwmStep]);

currentPwmStep++;

if (currentPwmStep >= sizeof(pwmValues) / sizeof(pwmValues[0])) {

motorStatus = RUNNING;

stepTime.stop();

stepTime.reset();

}

}

}

void shutDown() {

if (current < 5 && motorStatus == RUNNING) {

digitalWrite(relayPin, LOW); // Turn off the ignition relay

analogWrite(pwmPin, 15); // Set PWM to 5% (reduce alternator load)

if (!shutTime.started()) {

shutTime.start(); // Start the shutdown timer

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off)

motorStatus = WAITING; // Revert to WAITING state

shutTime.stop(); // Stop the timer

shutTime.reset(); // Reset the timer

}

}

}

void failState() { // Handle failed start attempts, overvoltage etc.

if (startTry == 5) { // Failed start

motorStatus = FAIL;

digitalWrite(starterPin, LOW); // Starter relay off

digitalWrite(relayPin, LOW); // Ignition switch relay off

lcd.setCursor(0, 0); // On lcd print "Engine start failed"

lcd.print("K");

lcd.print((char)0xe1);

lcd.print("ynnistys ");

lcd.setCursor(0, 1);

lcd.print("ep");

lcd.print((char)0xe1);

lcd.print("onnistui ");

} else if (sensVoltage >= 15) { // Overvoltage

motorStatus = FAIL;

digitalWrite(relayPin, LOW);

lcd.setCursor(0, 0); // On lcd print "Overvoltage"

lcd.print("Ylij");

lcd.print((char)0xe1);

lcd.print("nnite ");

lcd.setCursor(0, 1);

lcd.print(" ");

if (!shutTime.started()) {

shutTime.start(); // Start the shutdown timer

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off)

shutTime.stop(); // Stop the timer

shutTime.reset(); // Reset the timer

}

} else if ((rpm <= 900 || rpm >= 3700) && motorStatus == RUNNING) { // RPM sensor

motorStatus = FAIL;

digitalWrite(relayPin, LOW);

lcd.setCursor(0, 0); // On lcd print "Faulty rpm"

lcd.print("Kierrosluku ");

lcd.setCursor(0, 1);

lcd.print("virheellinen ");

if (!shutTime.started()) {

shutTime.start(); // Start the shutdown timer

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off)

shutTime.stop(); // Stop the timer

shutTime.reset(); // Reset the timer

}

// } else if (motorStatus == RUNNING) { // Vibration sensor

// if (digitalRead(motorPin) == LOW) {

// if (!sensorTime.started()) {

// sensorTime.start(); // Start the sensor blackout timer

// }

// if (sensorTime.done()) {

// motorStatus = FAIL;

// analogWrite(pwmPin, 255);

// lcd.setCursor(0, 0); // On lcd print "Faulty vibration signal"

// lcd.print("Virheellinen");

// lcd.setCursor(0, 1);

// lcd.print("V");

// lcd.print((char)0xe1);

// lcd.print("rin");

// lcd.print((char)0xe1);

// lcd.print("signaali");

// lcd.print(" ");

// sensorTime.stop();

// sensorTime.reset();

// }

// } else { // If signal reverts to normal during the time, stop timer

// sensorTime.stop();

// sensorTime.reset();

}

}

//}

void lcdDisplay() {

if (motorStatus == RUNNING) {

lcd.setCursor(0, 0);

lcd.print("Virta: ");

lcd.print(current);

lcd.print(" A ");

lcd.setCursor(0, 1);

lcd.print("J");

lcd.print((char)0xe1);

lcd.print("nnite: ");

lcd.print(sensVoltage);

lcd.print(" V ");

} else if (motorStatus == WAITING || motorStatus == STARTING) {

lcd.setCursor(0, 0);

lcd.print("Odottaa... ");

lcd.setCursor(0, 1);

lcd.print("J");

lcd.print((char)0xe1);

lcd.print("nnite: ");

lcd.print(sensVoltage);

lcd.print(" V ");

}

}

void loop() {

// Calculate current from sensor reading

// Calculate the charging current from the average and display it on the LCD screen.

// Take N readings and store them in the array

// for (int i = 0; i < N; i++) {

// readings[i] = analogRead(currentPin);

// delay(1); //Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sum = 0;

// for (int i = 0; i < N; i++) {

// sum += readings[i];

// }

// float average = sum / N;

// float voltage = average * voltageFactor; // Convert ADC reading to voltage

// current = (m * voltage + b) * currentCal; // Convert voltage to current using the linear equation, correct with current calibration value if needed

// Calculate high voltage from voltage divider input

// Calculate the charging voltage from the average and display it on the LCD screen.

// Take Y readings and store them in the array

// for (int j = 0; j < Y; j++) {

// readingsV[j] = analogRead(voltagePin);

// delay(1); // Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sumV = 0;

// for (int j = 0; j < Y; j++) {

// sumV += readingsV[j];

// }

// float averageV = sumV / Y;

// float voltageV = averageV * voltageFactor; // Convert ADC reading to voltage

// sensVoltage = voltageV * sensVfactor; // Convert voltage to real voltage

// RPM Calculation from Hall Sensor input

// {

// duration = pulseIn(rpmPin, FALLING, 500000); // Times the amount of microseconds the motor is not timing IR, Times out after 100000 uS. Raise the timeout for slower RPM readings. .5 second

// rpm = 60000.0 / duration * 1000; // See above

// }

// Simulate sensor readings via Serial input

if (Serial.available() > 0) {

char input = Serial.read();

switch (input) {

case '1':

rpm = 0;

break;

case '2':

rpm = 500;

break;

case '3':

rpm = 2000;

break;

case 'a':

current = 2;

break;

case 'b':

current = 20;

break;

case 'c':

current = 80;

break;

case 'z':

sensVoltage = 11;

break;

case 'x':

sensVoltage = 14;

break;

case 'y':

sensVoltage = 16;

break;

default:

Serial.println("Invalid input.");

return;

}

}

// Handle motor status

switch (motorStatus) {

case WAITING:

motorCrankState();

break;

case STARTING:

crank();

Waiter();

break;

case STARTED:

motorRunning();

break;

case RAMP_UP:

rampUp();

break;

case RUNNING:

shutDown();

break;

}

lcdDisplay();

failState();

// Debug output

Serial.print("Voltage: ");

Serial.print(sensVoltage);

Serial.print(" V, Current: ");

Serial.print(current);

Serial.print(" A, RPM: ");

Serial.print(rpm);

Serial.print(", Status: ");

Serial.println(motorStatus);

}

Viimeksi muokattu:

Huhhuh, pakko laittaa koodi tänne, kun olen tehnyt siihen muutoksia. Pelkään, etten vain tee sille kohta "meisselihalvausta".

Muutoksia:

-FAIL tilalle käyttöä, esim. ylijännite ja epäonnistunut käynnistys, mutta myös nyt kierroluvun tarkastelu. Lisäsin myös samalla tyylillä värinäanturin tarkastelun, mutta voi olla, että koko anturi jätetään pois, koska kierroslukuanturi tulee olemaan keskeinen tätä systeemiä käynnistyksen vuoksi.

-lcd:tä päivitetty

-käynnistysfunktiossa (crank()) puuttui ajastimen sammutus ja nollaus, mikäli jännite heilahtelee ylös. Tämä on hyvin todennäköinen tilanne. Hyvin näytti pelevaan simulaattorissa, vaikka tuossa nyt tulee tuo else -ehto, mutta käsittääkseni tuo switch-case -kombinaatio ehkäisee tuon ajamista koko ajan.

Ja seuraavana, jos koodi vielä toimii, tulisi testata vielä fyysisesti skoopilla PWM sekä releet. Releet pitää käskyttää niin (HIGH/LOW), että sytytysvirtarele ei johda, kun sille ei anneta käskyä ja starttireleen ei myöskään johda, ku sitä ei käskytetä. Toki releestä voi vaihtaa nuo kummin päin vaan. Pitää vaan varmistua, ettei myöskään koodissa ole mitään ristiriitojen releiden ohjauksessa niin, että rele voisi jäädä väärään asentoon. Siltä se ei Arduino simulaattorin mukaan näytä, mikä on hyvä asia.

switch-case on loogisesti sama kuin if () else if () else if () jne.

Releet pitää kytkeä niin että käynnistettäessä ne ovat siinä tilassa jossa pitää ollakin ilman että käännetään setup- funktiossa "oletustilaan".

Eli todennäköisesti sammutusrele pitää moottorin sammuneena ja käynnistysrele on irti. Näin tehden moottori sammuu jos arduinolta lähtee sähköt joka vastaa tietysti virrat laitetaan päälle tilannetta.

Ja muista että releessä on kytkentäviive, yleisesti joku 100-200ms on turvallinen oletus mutta riippuu releestä.

- Liittynyt

- 10.07.2017

- Viestejä

- 958

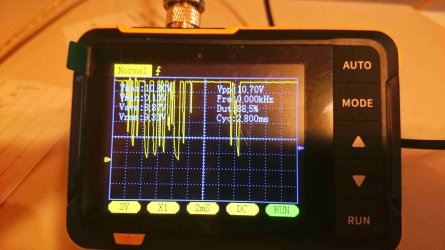

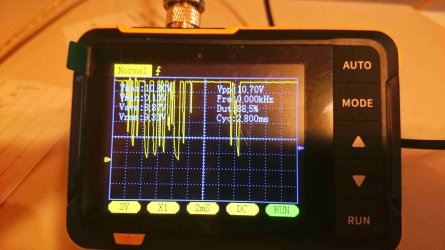

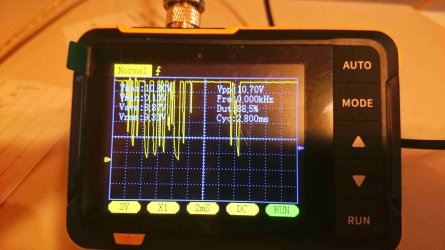

Testailin koodia nyt kortin kanssa, vielä releet on testaamatta ja muuten koko hössäkkä 12 voltin virtalähteellä. Toivotaan, ettei tule mitään yllätyksiä enää, mutta hyvältä näyttää.

PWM näytti skoopilla toimivan täysin oikein, joskin kerran onnistuin tekemään niin, ettei PWM lähtenyt nousemaan. En saanut toistettua sitä, mutta johtui varmaan liian äkäisistä komennoista, eikä käytännön toteutuksessa voi esiintyä esim. kierrosten hyppäämistä nollasta 500:een r/min millisekunneissa ja koodissahan on ylijännitesuojakin.

Tein vähän pienimuotoisia muutoksia taas, esim. lcd on nyt keskitetty täysin omaan funktioonsa. On ne vaan käteviä nuo #define -makrot tässäkin, mutta onko niiden käytöllä jotain miinuspuolia?

PWM näytti skoopilla toimivan täysin oikein, joskin kerran onnistuin tekemään niin, ettei PWM lähtenyt nousemaan. En saanut toistettua sitä, mutta johtui varmaan liian äkäisistä komennoista, eikä käytännön toteutuksessa voi esiintyä esim. kierrosten hyppäämistä nollasta 500:een r/min millisekunneissa ja koodissahan on ylijännitesuojakin.

Tein vähän pienimuotoisia muutoksia taas, esim. lcd on nyt keskitetty täysin omaan funktioonsa. On ne vaan käteviä nuo #define -makrot tässäkin, mutta onko niiden käytöllä jotain miinuspuolia?

C++:

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

#include <neotimer.h>

// System status variables

#define WAITING 0

#define STARTING 1

#define STARTED 2

#define RAMP_UP 3

#define RUNNING 4

#define FAIL 5

// Fail state LCD display

#define FAILED_START 1

#define OVERVOLTAGE 2

#define FAILED_RPM 3

#define FAILED_VIBSENSOR 4

// Pin definitions

const int currentPin = A0;

const int voltagePin = A2;

const int motorPin = 2;

const int pwmPin = 9;

const int relayPin = 4;

const int rpmPin = 11;

const int starterPin = 3;

// Timers

Neotimer motorTime = Neotimer(10000); // 10 seconds for startup detection

Neotimer stepTime = Neotimer(1000); // 1 second for PWM step interval

Neotimer shutTime = Neotimer(15000); // 15 seconds for engine shutdown

Neotimer crankTime = Neotimer(4000); // 4 seconds for cranking

Neotimer crankWait = Neotimer(5000); // 5 seconds wait after failed crank

Neotimer voltageWait = Neotimer(10000); // 10 seconds wait for undervoltage

Neotimer sensorTime = Neotimer(5000); // 5 seconds check time for vibration sensor condition on RUNNNING status

// LCD

LiquidCrystal_I2C lcd(0x27, 16, 2);

// Variables

int motorStatus = WAITING;

int startTry = 0;

int startInterval = 0; // Waiting time on after start attempt

int currentPwmStep = 0;

int pwmValues[] = { 15, 53, 91, 129 }; // PWM steps

int lcdFail = 0; // LCD fail state display

// Current and voltage calculation

float voltageFactor = 5.00 / 1023.00; // Factor to convert ADC reading to voltage

// Define the points for current calculation / the line equation

float x1 = 0.500; // volts

float y1 = 0; // amps

float x2 = 4.005; // volts

float y2 = 150; // amps

// Calculate the slope and intercept

float m = (y2 - y1) / (x2 - x1);

float b = y1 - m * x1;

float currentCal = 1; // Variable to shift the whole current level

float sensVfactor = 20.00 / 4.9248; // 4.9248 volts = 20 volts, factor to convert high voltage to 0-5 V

const int N = 25; // Number of current readings to average

const int Y = 25; // Number of sensed voltage readings to average

int readings[N]; // Array to store the current readings

int readingsV[Y]; // Array to store the sensed voltage readings

float sensVoltage = 12.0; // Example voltage

float current = 0.0; // Example current

//RPM Calculation

int rpm = 0; //unsigned long rpm = 0;

unsigned long duration; // Sensor pulse in duration

void setup() {

Serial.begin(250000);

// Change timers on pins to change PWM freq to 122 Hz

// Pins D9 and D10 - 122 Hz

TCCR1A = 0b00000001; // 8bit

TCCR1B = 0b00000100; // x256 phase correct

// Initialize I2C and check if LCD is connected

Wire.begin();

Wire.beginTransmission(0x27);

if (Wire.endTransmission() == 0) {

// LCD is connected, proceed with initialization

lcd.begin(16, 2);

lcd.backlight();

lcd.clear();

} else {

// LCD is not connected, continue without initializing the LCD

Serial.println("LCD not connected. Skipping.");

}

// Pin modes

pinMode(currentPin, INPUT);

pinMode(voltagePin, INPUT);

pinMode(motorPin, INPUT_PULLUP);

pinMode(pwmPin, OUTPUT);

pinMode(relayPin, OUTPUT);

pinMode(rpmPin, INPUT_PULLUP);

pinMode(starterPin, OUTPUT);

analogWrite(pwmPin, 255); // Start with PWM off

}

void motorCrankState() {

if (sensVoltage < 11.9 && motorStatus == WAITING) {

if (!voltageWait.started()) {

voltageWait.start();

}

if (voltageWait.done()) {

motorStatus = STARTING;

digitalWrite(relayPin, HIGH); // Relay on

voltageWait.stop();

voltageWait.reset();

}

} else {

voltageWait.stop();

voltageWait.reset();

}

}

void crank() {

if (startTry < 5 && startInterval == 0) {

if (rpm <= 300) { // If motor runs slower than this, switch starter relay on

digitalWrite(starterPin, HIGH);

if (!crankTime.started()) {

crankTime.start();

}

if (crankTime.done()) { // If max cranking time finished without succeeding start, switch starter relay off

digitalWrite(starterPin, LOW);

crankTime.stop();

crankTime.reset();

startTry++;

startInterval = 1;

}

} else if (rpm > 300) { // If motor runs faster than this, switch starter relay off

digitalWrite(starterPin, LOW);

startTry = 0;

motorStatus = STARTED;

crankTime.stop();

crankTime.reset();

}

}

}

void Waiter() {

if (startInterval == 1) {

if (!crankWait.started()) {

crankWait.start();

}

if (crankWait.done()) {

startInterval = 0;

crankWait.stop();

crankWait.reset();

}

}

}

void motorRunning() {

if ((rpm > 1800 || digitalRead(motorPin) == HIGH) && motorStatus == STARTED) {

if (!motorTime.started()) {

motorTime.start();

}

if (motorTime.done()) {

motorStatus = RAMP_UP;

motorTime.stop();

motorTime.reset();

}

}

}

void rampUp() {

if (stepTime.repeat()) {

analogWrite(pwmPin, pwmValues[currentPwmStep]);

currentPwmStep++;

if (currentPwmStep >= sizeof(pwmValues) / sizeof(pwmValues[0])) {

motorStatus = RUNNING;

stepTime.stop();

stepTime.reset();

}

}

}

void shutDown() {

if (current < 5 && motorStatus == RUNNING) {

digitalWrite(relayPin, LOW); // Turn off the ignition relay

analogWrite(pwmPin, 15); // Set PWM to 5% (reduce alternator load)

if (!shutTime.started()) {

shutTime.start(); // Start the shutdown timer

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off)

motorStatus = WAITING; // Revert to WAITING state

shutTime.stop(); // Stop the timer

shutTime.reset(); // Reset the timer

}

}

}

void failState() { // Handle failed start attempts, overvoltage etc.

if (startTry == 5) { // Failed start

motorStatus = FAIL;

digitalWrite(starterPin, LOW); // Starter relay off

digitalWrite(relayPin, LOW); // Ignition switch relay off

lcdFail = FAILED_START;

} else if (sensVoltage >= 15) { // Overvoltage

motorStatus = FAIL;

digitalWrite(relayPin, LOW); // Ignition relay off

lcdFail = OVERVOLTAGE;

if (!shutTime.started()) {

shutTime.start(); // Start the shutdown timer

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off)

shutTime.stop(); // Stop the timer

shutTime.reset(); // Reset the timer

}

} else if ((rpm <= 900 || rpm >= 3700) && motorStatus == RUNNING) { // RPM sensor

motorStatus = FAIL;

digitalWrite(relayPin, LOW); // Ignition relay off

lcdFail = FAILED_RPM;

if (!shutTime.started()) {

shutTime.start(); // Start the shutdown timer

}

if (shutTime.done()) {

analogWrite(pwmPin, 255); // Set PWM to 100% (alternator electromagnet off)

shutTime.stop(); // Stop the timer

shutTime.reset(); // Reset the timer

}

// } else if (motorStatus == RUNNING) { // Vibration sensor

// if (digitalRead(motorPin) == LOW) {

// if (!sensorTime.started()) {

// sensorTime.start(); // Start the sensor blackout timer

// }

// if (sensorTime.done()) {

// motorStatus = FAIL;

// analogWrite(pwmPin, 15);

// lcd.setCursor(0, 0); // On lcd print "Faulty vibration signal"

// lcd.print("Virheellinen");

// lcd.setCursor(0, 1);

// lcd.print("V");

// lcd.print((char)0xe1);

// lcd.print("rin");

// lcd.print((char)0xe1);

// lcd.print("signaali");

// lcd.print(" ");

// sensorTime.stop();

// sensorTime.reset();

// }

// } else { // If signal reverts to normal during the time, stop timer

// sensorTime.stop();

// sensorTime.reset();

}

}

//}

void lcdDisplay() {

if (motorStatus == RUNNING || motorStatus == RAMP_UP) {

lcd.setCursor(0, 0);

lcd.print("Virta: ");

lcd.print(current);

lcd.print(" A ");

lcd.setCursor(0, 1);

lcd.print("J");

lcd.print((char)0xe1);

lcd.print("nnite: ");

lcd.print(sensVoltage);

lcd.print(" V ");

} else if (motorStatus == WAITING) {

lcd.setCursor(0, 0);

lcd.print("Odottaa... ");

lcd.setCursor(0, 1);

lcd.print("J");

lcd.print((char)0xe1);

lcd.print("nnite: ");

lcd.print(sensVoltage);

lcd.print(" V ");

} else if (motorStatus == STARTING || motorStatus == STARTED) {

lcd.setCursor(0, 0);

lcd.print("K");

lcd.print((char)0xe1);

lcd.print("ynnistet");

lcd.print((char)0xe1);

lcd.print((char)0xe1);

lcd.print("n");

lcd.setCursor(0, 1);

lcd.print("................");

} else if (lcdFail == FAILED_START) {

lcd.setCursor(0, 0); // On lcd print "Engine start failed"

lcd.print("K");

lcd.print((char)0xe1);

lcd.print("ynnistys ");

lcd.setCursor(0, 1);

lcd.print("ep");

lcd.print((char)0xe1);

lcd.print("onnistui ");

} else if (lcdFail == OVERVOLTAGE) {

lcd.setCursor(0, 0); // On lcd print "Overvoltage"

lcd.print("Ylij");

lcd.print((char)0xe1);

lcd.print("nnite ");

lcd.setCursor(0, 1);

lcd.print(" ");

} else if (lcdFail == FAILED_RPM) {

lcd.setCursor(0, 0); // On lcd print "Faulty rpm"

lcd.print("Kierrosluku ");

lcd.setCursor(0, 1);

lcd.print("virheellinen ");

}

}

void loop() {

// Calculate current from sensor reading

// Calculate the charging current from the average and display it on the LCD screen.

// Take N readings and store them in the array

// for (int i = 0; i < N; i++) {

// readings[i] = analogRead(currentPin);

// delay(1); //Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sum = 0;

// for (int i = 0; i < N; i++) {

// sum += readings[i];

// }

// float average = sum / N;

// float voltage = average * voltageFactor; // Convert ADC reading to voltage

// current = (m * voltage + b) * currentCal; // Convert voltage to current using the linear equation, correct with current calibration value if needed

// Calculate high voltage from voltage divider input

// Calculate the charging voltage from the average and display it on the LCD screen.

// Take Y readings and store them in the array

// for (int j = 0; j < Y; j++) {

// readingsV[j] = analogRead(voltagePin);

// delay(1); // Wait for a millisecond between readings

// }

// Calculate the average of the N readings

// float sumV = 0;

// for (int j = 0; j < Y; j++) {

// sumV += readingsV[j];

// }

// float averageV = sumV / Y;

// float voltageV = averageV * voltageFactor; // Convert ADC reading to voltage

// sensVoltage = voltageV * sensVfactor; // Convert voltage to real voltage

// RPM Calculation from Hall Sensor input

// {

// duration = pulseIn(rpmPin, FALLING, 500000); // Times the amount of microseconds the motor is not timing IR, Times out after 100000 uS. Raise the timeout for slower RPM readings. .5 second

// rpm = 60000.0 / duration * 1000; // See above

// }

// Simulate sensor readings via Serial input

if (Serial.available() > 0) {

char input = Serial.read();

switch (input) {

case '1':

rpm = 0;

break;

case '2':

rpm = 500;

break;

case '3':

rpm = 2000;

break;

case 'a':

current = 2;

break;

case 'b':

current = 20;

break;

case 'c':

current = 80;

break;

case 'z':

sensVoltage = 11;

break;

case 'x':

sensVoltage = 14;

break;

case 'y':

sensVoltage = 16;

break;

default:

Serial.println("Invalid input.");

return;

}

}

// Handle motor status

switch (motorStatus) {

case WAITING:

motorCrankState();

break;

case STARTING:

crank();

Waiter();

break;

case STARTED:

motorRunning();

break;

case RAMP_UP:

rampUp();

break;

case RUNNING:

shutDown();

break;

}

lcdDisplay();

failState();

// Debug output

Serial.print("Voltage: ");

Serial.print(sensVoltage);

Serial.print(" V, Current: ");

Serial.print(current);

Serial.print(" A, RPM: ");

Serial.print(rpm);

Serial.print(", Status: ");

Serial.print(motorStatus);

Serial.print(", Start try: ");

Serial.print(startTry);

Serial.print(", Start wait: ");

Serial.println(startInterval);

}

Viimeksi muokattu:

Testailin koodia nyt kortin kanssa, vielä releet on testaamatta ja muuten koko hössäkkä 12 voltin virtalähteellä. Toivotaan, ettei tule mitään yllätyksiä enää, mutta hyvältä näyttää.

PWM näytti skoopilla toimivan täysin oikein, joskin kerran onnistuin tekemään niin, ettei PWM lähtenyt nousemaan. En saanut toistettua sitä, mutta johtui varmaan liian äkäisistä komennoista, eikä käytännön toteutuksessa voi esiintyä esim. kierrosten hyppäämistä nollasta 500:een r/min millisekunneissa ja koodissahan on ylijännitesuojakin.

Tein vähän pienimuotoisia muutoksia taas, esim. lcd on nyt keskitetty täysin omaan funktioonsa. On ne vaan käteviä nuo #define -makrot tässäkin, mutta onko niiden käytöllä jotain miinuspuolia?

Hyvä että lähtee toimimaan.

Tässä miinuksia ei juuri ole.

Tietysti pitää keksiä aina sellaiset arvot joita ei ole käytetty muualla eli voi käydä niin että jossakin kirjastossa on jo määritettynä vaikka OK ja FAIL niin niitä ei sitten voi yliajaa. Kääntäjän pitäisi kyllä herjata jos on päällekkäisiä.

Ja tietysti jos tekee merkkijonoja tai monimutkaisempia juttuja niin voi joutua tyypittämään erikseen jne.

Itse ehkä käyttäisin samaa motorStatus- muuttujaa myös tuolla näytössä kaikille tiloille tai näytölle kokonaan omat tilat eikä kahta sekaisin.

Voit myös tehdä näin:

C++:

switch(muuttuja) {

case ARVO1:

// tehdään jotain

break;

case ARVO2:

case ARVO3:

// tehdään muuta

break;

default:

// "else"

break;

}If- rakenteena tuo olisi

C++:

if (muuttuja == ARVO1) {

// tehdään jotain

} else if ( (muuttuja == ARVO2) || (muuttuja == ARVO3)) {

// tehdään muuta

} else {

// "else"

}= jos ei ole break- määritystä niin switch juoksee case- kohtia läpi kunnes loppuu tai tulee break.

Yksi vaihtoehto on myös pilkkoa tuosta lcdDisplay:stä jokainen if-haara omaksi funktiokseen tyyliin lcdPrintStarting(), lcdPrintWaiting() jne. Niitä sitten kutsuttaisiin loopin switch casesta. Lyhyet funktiot on yleisesti helpompia hahmottaa ja debugata.

Näistä kohdista voisi ottaa tuon status-vertailun pois kokonaan.

Se on aina true, koska funktiota kutsutaan loopista vain silloin kun tila on oikea. Koodista tulee helppolukuisempaa, kun tuollaiset turhat ottaa pois.